FIXTURED MULTIPLES |

MOBILE ASSEMBLY STATION

Maximize your flexibility and take your fastening processes where and when you need them

FEATURES

- Synatec HLT 15 Display

- Error Proofing and Data Collectio

- Sequence tightening and counting function

- Integrated Cable Management

CONTROL SYSTEM

- Power Focus 4000 Graph Tightening Controller

- IRC Focus Controller

- Synatec Software and PC for tightening control

- Uninterruptable Power Supply (UPS)

- Compartmen

MECHANICS

- Woodwork Surface

- 1 – Keyboard Drawer

- 3 – Storage Drawers

- Worksurface Connection Port 2 – Power Socket, 1 – Ethernet (LAN) and 1 – USB

- Controller Mounting Cabinet

- Push / Pull Handle

- Cable Reel and Power Cable

- Removable Back Walls with Ventilation Slots

- 2 – Fixed Castors and 2 – Swivel Castors with Brake

- 2 – Tool Holders – Side-mounted

- STWrench

- ETV STB33-30

- ETV ST61-50

SUSPENDED FRAME

A compact, evolving solution for all work environments

MECHANICS

- 2 – Trolley Carriage Mounts

- Controller suspended frame with adjustable height

- Controller mounting plate and cable cover plate

- Accessories mounting brackets • Stacklight • Accessory Shelf

- ETP STB33-12 with tool holder • ETV STB63-50 with tool holder

- Selector 4 Socket Tray • Operator Panel

FEATURES

- Adjustable height of controller mounting and accessories

- Integrated Cable Management

- Mobile for flexible manufacturing

CONTROL SYSTEM

- Power Focus 4000 Compact Tightening Controller

- Power MACS 4000 Floor Stand • Pneumatic Control System

- Indicator Box with E-Stop • MiniDisplay

- Start Handle with forward/reverse

BENEFITS

- Saves valuable floor space • Easy install and maintenance

- Durable construction and light weight for ease of handling

- Workstation optimization

WHEEL NUT SECURE – SMALL BOLT PATTERN

Compact Horizo ntal Rotate Fixture HR1 with Air Cylinder

ntal Rotate Fixture HR1 with Air Cylinder

MECHANICS

- QST50-150CT

- Air cylinder auto balancer with guiding and safety belt

- 4 – trolley carriage between single rail and run way rails, 1 – trolley carriage with air motor

- Cable chain for cable management

- 2-Trolley Carriage with Single Bridge Rai

FEATURES

- Touch Screen MiniDisplay as operation interface

- Fixture rotation for spindle compliance to fasteners

- Light up/down movement with near zerogravity air balance assistance

- Short operation time

- Automatic “return to home” positioning

- Low impact forward/backward movement

- E-Stop for whole system

BENEFITS

- Light-weight, modular fixture for easy operator handling and ergonomics

- Reduces work–related injury

- Efficiency in production

- Synchronized multi-spindles to reduce cycle time and to evenly distribute fastener clamp load

- Tightening results including OK, NOK, Data and traces show on MiniDisplay and indicator box

- Easy Maintenance

MAIN BEARING CAP SECURE

1-Spindle vertical fixture with high torque reaction suspension.

MECHANICS

- Atlas Copco WP Spring balancer with up/ down guiding to take torque reaction force

- 4 – trolleys with top plate interface to rails

- Double aluminum rails with three cable trolleys

- QST62-230CT

FEATURES

- Simple 1-Spindle Vertical Fixture for easy operation

- Up/down movement guiding to take torque reaction force

- Spring balancer for up/down movement, no air supply needed

- Safety belt for machine fall down protection

- Express indicator box with Estop to show tightening results OK,NOK.

CONTROL SYSTEM

- Power MACS 4000 Tightening System

- Power MACS 4000 Floor Stand

- Indicator box with E – Stop

- Standard Operator Handle Kit with forward/reverse

BENEFITS

- Light-weight, modular fixture for easy operator handling and ergonomics

- Adjustable handle mounting for custom positioning

- Easy up/down movement by spring balancer

- Hard connection to rails and up/down movement guiding suspension makes angle control possible

- Easy Maintenance

HAND TOOL SUSPENSION – HTS1

1-Spindle vertical fixture HTS1.

MECHANICS

- 2 – Trolley Carriage and Single Top Rail

- HTS1 (150 Nm) with WP Spring Balancer

- Fixed Clamp Angle Tool Holder

- ETV STB63-100

FEATURES

- Torque reaction up to 150 Nm

- Smooth up/down movement

- Adjustable total length with upper extension tube

- Cable management

- Safety wire for fall prevention

CONTROL SYSTEM

- Power Focus 4000 Compact Tightening Controller

- Controller mounting plate

BENEFITS

- Absorbs torque reaction generated by the tool, eliminating the operator impact

- Lightweight and smooth movement for ease of handling

- Low handling forces for improved ergonomic

- Easy to install and maintain

WHEEL NUT SECURE – LARGE BOLT PATTERN

2-Spindle horizontal rotate fixture HR3 with air cylinder suspension

MECHANICS

- Up/down Air Cylinder Suspension with stay put function

- 2-Trolley Carriage with Single Bridge Rail and Three Trolley for cables

- Dual Torque Reaction Device

- QST80-600CT

FEATURES

- Fixture rotation for spindle compliance to fasteners

- 200 mm vertical suspension travel with Air Cylinder

- Safety belt for fall protection

- Up to 15 programs can be selected on Operator Panel

CONTROL SYSTEM

- Power MACS 4000 Tightening System

- Power MACS 4000 Floor Stand

- Advanced Operator Panel with E-Stop

- Start Handle with forward/reverse

BENEFITS

- Light-weight, modular fixture for easy operator handling and ergonomics

- Adjustable handle mounting for custom positioning

- Synchronized multi-spindles to reduce cycle time

- Torque Reaction device to protect operator and improve safety

- Air cylinder suspension for easy up/down movement control

- Tightening results with counting are shown in front operator

- Different programs are available to select for different products

- Easy Maintenance

CYLINDER HEAD SECURE

1-Spindle vertical fixture articulated arm with PRS.

MECHANICS

- 1000 Nm Articulated Arm with Balance Control

- Rotational spindle mounting plate with Standard Operator Handle Kit

- Vertical extension tube

- Parking Brake

- ETD ST101-1000

FEATURES

- ComNode III with Position Recognition Software (PRS)

- Barcode Scanner for part identification

- Articulated Arm Home Position Lock and Parallel Arm Cradle

- 3-Axis Encoder Package

CONTROL SYSTEM

- Power Focus 4000 Graph Tightening Controller

- ComNode III

- Position Recognition System (PRS)

BENEFITS

- Error-proofing system for improved quality and increased productivity

- Maintain a high quality standard regardless of operator

- Reduce the need for additional quality checks

- Ensures all process documentation is available per application and fastener

- Data collection

- Easy Maintenance

CUSTOMIZED SOLUTIONS

Designed for heavy truck wheel nuts tightening, this solution provides 5bolts synchronized tightening, with air cylinder assistant for up/down movement and forward/backward movement to ensure good ergonomic during operations, rigid up/down guiding suspension and light horizontal rotation makes easy bolts engagement for operator.

Mechanics

- Double bridge rails

- Four trolleys carriage with push in/out rod less air cylinder

- Air cylinder suspension for up/down movement, with lock function and guiding tube

- Horizontal rotational multiple with express handles

- Customized operator panel with lamps, program switches and E stop push button

Control System

- PowerMacs 4000 control system with floor stand for

controller mounting

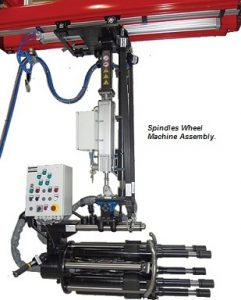

Designed for heavy truck wheel nuts tightening where the production cycle is slow, this solution provides 2bolts synchronized tightening, with air cylinder or spring balancer for up/down movement, there is brake on rear of multiple to stop multiple rotation during tightening work, which minimize the injury risk to operator due to rotation of multiple in case of one spindle breaks during tightening. Spindles distance can be adjusted to adapt different bolts patterns on the line.

Mechanics

- Double or single bridge rails

- Four or two trolleys carriage

- Air cylinder suspension for up/down movement, with lock function

- Horizontal rotational multiple with express handles, brakes mechanism on back side of multiple, pitch change mechanism on front mounting plate of multiple

- Customized operator panel with lamps, program switches and E stop push button

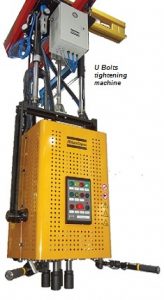

Designed for U bolts tightening, this solution provides four bolts synchronized tightening, ensuring the clamp force on the joint of this critical part in the truck or bus, air cylinder will be provided for up/down movement with guiding tubes sitting beside it.

Mechanics

- Double bridge rails

- Four trolleys carriage

- Air cylinder suspension for up/down movement, with lock function and guiding tube

- Vertical multiple with four QST spindles inside, which can be adjusted to be tilt according to work situation

- Operator panel with lamps, program switches and E stop push button, express handlesS

Control System

- PowerMacs 4000 control system with floor stand for controller mounting

Designed for truck hub nuts tightening and rolling drag check simultaneously, we use coaxial spindles solution to eliminate manual process steps, without validation on the preload checking on the bearing, at same time, it provides additional flexibility in tooling by allowing various part models and parameter selection that can be made by socket change, barcode reader, or other means. As result, It prove the quality,productivity and flexibility to the truck manufacturing.

Mechanics

- Double bridge rails

- Four trolleys carriage

- Air cylinder suspension for up/down movement, with lock function and guiding tube

- Horizontal coaxial spindles multiple with express handles, fixtures

- Operator panel with lamps, program switches and E stop push button.

By using simple jib and spring balancer, operator will save handling force of Tensor ST Revo tool, which can also cover enough big working area with jib for different bolts tightening.

SAIPA

www.saipacorp.com

شرکت بن رو

www.saipacorp.com

شرکت سامیار کاشان

www.saipa-k.com

شرکت پارس خودرو

www.parskhodro.ir

خیابان ملاصدرا ، بین شیخ بهایی و شیراز ، پلاک ۱۲۷ ، طبقه ۲ ، واحد ۹

تلفکس : ۸ – ۲۲۹۲۳۹۷۷