specification irb 4400 :

Fast, compact and versatile industrial robot

The IRB 4400 is a compact robot that can handle loads up to 60 kg. Exceptional all-round capabilities and stiffness make IRB 4400 perfectly matched for variety of applications where accuracy, speed rigidity and flexibility are important.

Features and benefits :

• Fast acceleration and top speed – short cycle times

• Accurate – consistent parts quality

• Versatile – flexible integration and production

• Protected for harsh environments to IP 67 for the entire robot

– Optional FoundryPlus version – can be washed down with high pressure steam.

– Optional FoundryPrime version – for waterjet cleaning of castings and machined parts.

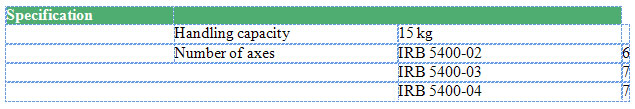

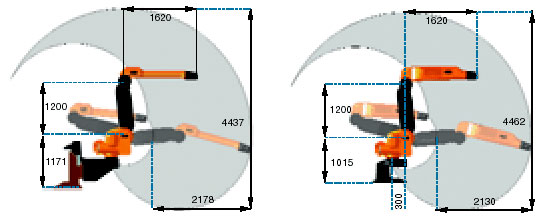

specification irb 5400 :

The FlexLine system provides paint solutions which maximize your performance and minimize your costs.

The IRB 5400 is a family of paint robots offering accurate painting, high uptime, low paint consumption, short cycle times and effective integration of paint application equipment. Additional benefits include an expansive working envelope, high load capacity and reliable operation. ABB’s unique Integrated Process System (IPS) features closed loop regulation and high-speed control for paint and airflow adjustment which minimizes overspray and secures a uniform film build.

The time and paint savings of the IRB 5400-series will impress you. By integrating colour change valves, pumps, flow sensors and air- and paint regulators into the arm of the IRB 5400, we have made the IRB 5400 one of the most reliable, cost-effective paint process robots in its class.

The IRB 5400 series comes in different versions:

• IRB 5400-12, Slim arm

• IRB 5400-13, Slim arm on Clean-wall rail

• IRB 5400-14, Slim arm on In-booth rail

• IRB 5400-22, Process robot

• IRB 5400-23, Process robot on Clean-wall rail

• IRB 5400-24, Process robot on In-booth rail

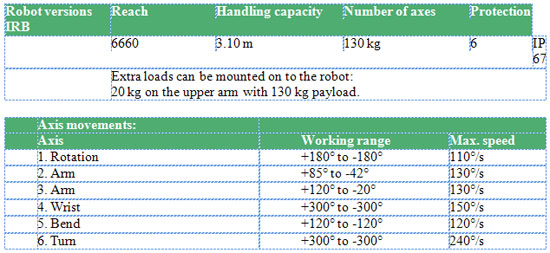

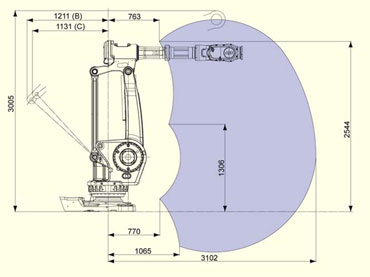

specification irb 6660 :

The optimised press tending robot

The main goal of IRB 6660 is to provide a faster robotics solution within the press tending application.

Concerning part transferring operations, it’s very important to reduce press occupation time. By improving the robot speed performance, the output of the press line is greatly increased.

• Optimised for press tending

The new striff design together wiht the long reach is perfect for high-performance press tending applications.

This results in high accuracy and uptime.

• A fast robot

This robot is fast, and 15% shorter cycle times are normally achieved inside the presses.

• High productivity

The overall cycle time is directly affected by using this faster robot, and so the line output.

• Longer lifetime

The most gears have been reinforced, gear life time is also improved when running fast in press tending.

Using proven components from the IRB 6600 family creates an extremely reliable robot.

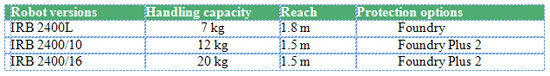

Technical data abb 2400 :

The IRB 2400 in its different versions and best accuracy gives excellent performance in material handling, machine tending and process applications. IRB 2400 offers you increased production rates, reduced lead times and faster delivery for your manufactured product.

• Reliable – High production up time

IRB 2400 is the world’s most popular industrial robot The robust construction and use of minimum parts contribute to high reliability and long intervals between maintenance.

• Fast – Short cycle times

Thanks to the ABB´s unique motion control of the robot optimizes the acceleration and retardation, which results in shortest cycle time possible.

• Accurate – Consistent parts quality

Best in class regarding path accuracy and position repeatability (RP = 0.06 mm)

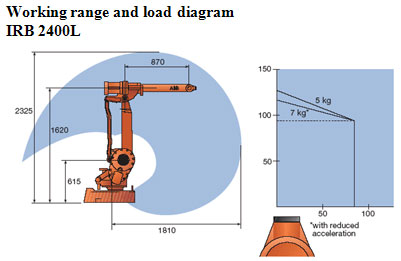

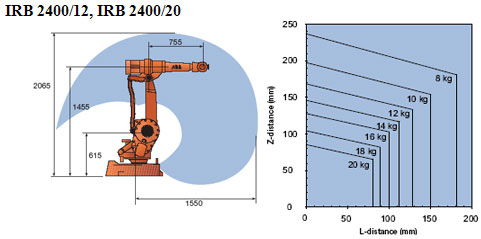

• Strong – Maximized utilization

Payload options are between 7 -20 kg. Max reach 1.810 m.

• Robust – Harsh production environment

IP 67 classified, steam washable, clean room (class 100) and “Foundry Plus” optional.

• Versatile – Flexible integration and production

All models offered with inverted mounting capability.

No6, Sharifi St, Shariati Ave, Tehran, IRAN

Tell:+98-21-22923977

Tel/Fax:+98-21-22923978